Tamas L’orant x Futuregrail

On December 6, 2023, we held our joint exhibition with the Fabergé jewelry house at the Singapore Opera Gallery. During the event, we presented my finished wristwatches and the mechanical movements from which I create special timepieces based on custom orders.

Around halfway through the evening, Mr. Ali Nael, co-owner of Futuregrail, approached me. He introduced himself and then picked up one of my works. I immediately noticed that he was a professional or colleague, as he instantly recognized the type, caliber, and age of the movement used in my unique watch. He then complimented the design and the quality of my work. In response to my question about whether we were colleagues, he modestly replied that no, he was just a collector and had a collection here in Singapore that he would be happy to show us. So, the next day, we took him up on his kind invitation.

The sight that greeted us was inexpressible! It turned out that we explored one of the largest and most valuable privately held watch collections in the world! This museum, which can only be visited by appointment, is the ultimate spot for mechanical watch enthusiasts: wristwatch and pocket watch rarities arranged in showcases spanning several hundred square meters! The only comparable sight I had seen was in Geneva, at the Patek Philippe Museum. There are even a few timepieces in their possession from Napoleon’s era that can’t be found in the aforementioned Swiss collection. They left me to immerse myself in this wonderful world with an understanding smile, and later, to help me “recover from the shock,” they offered me a seat and some refreshments.

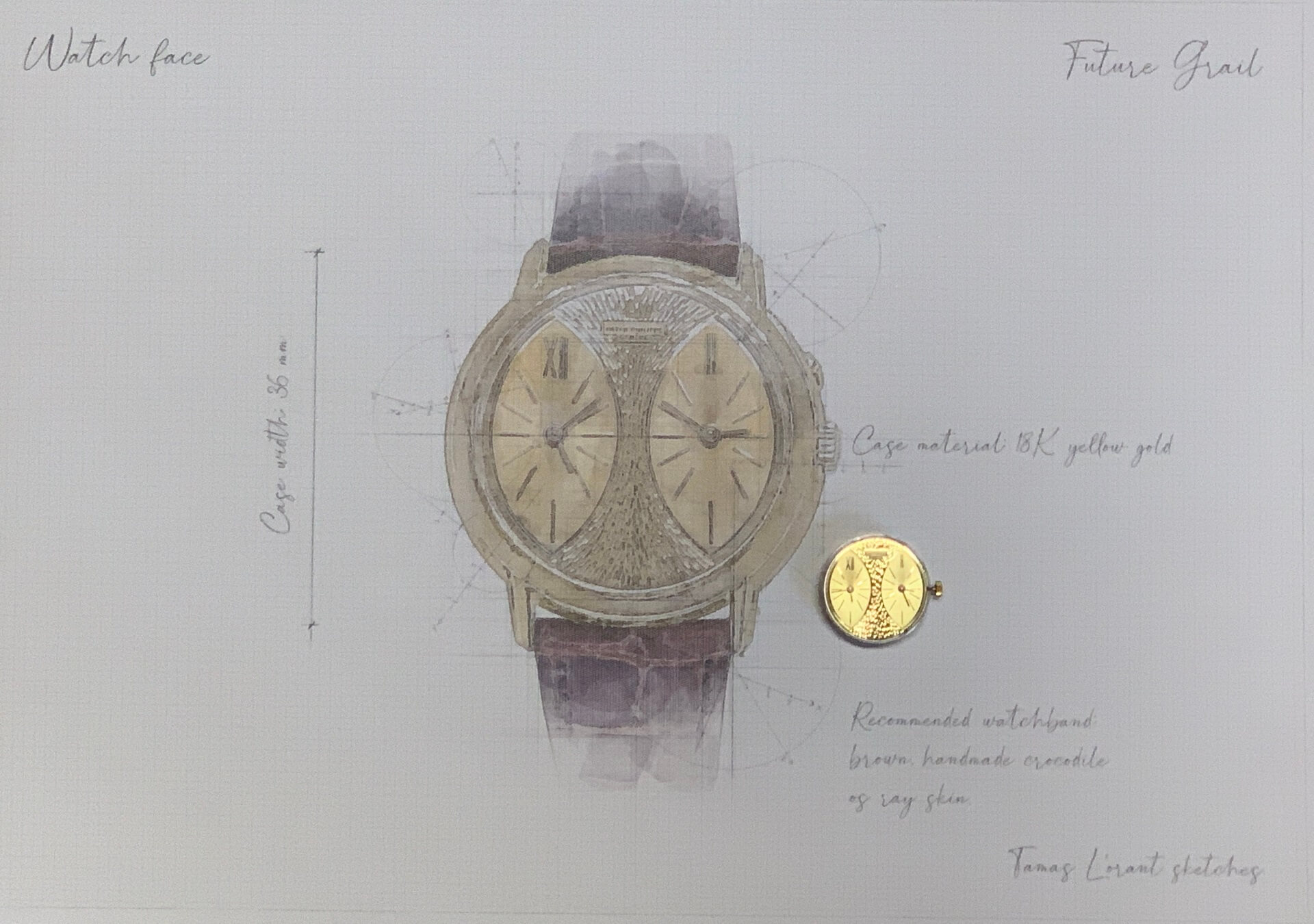

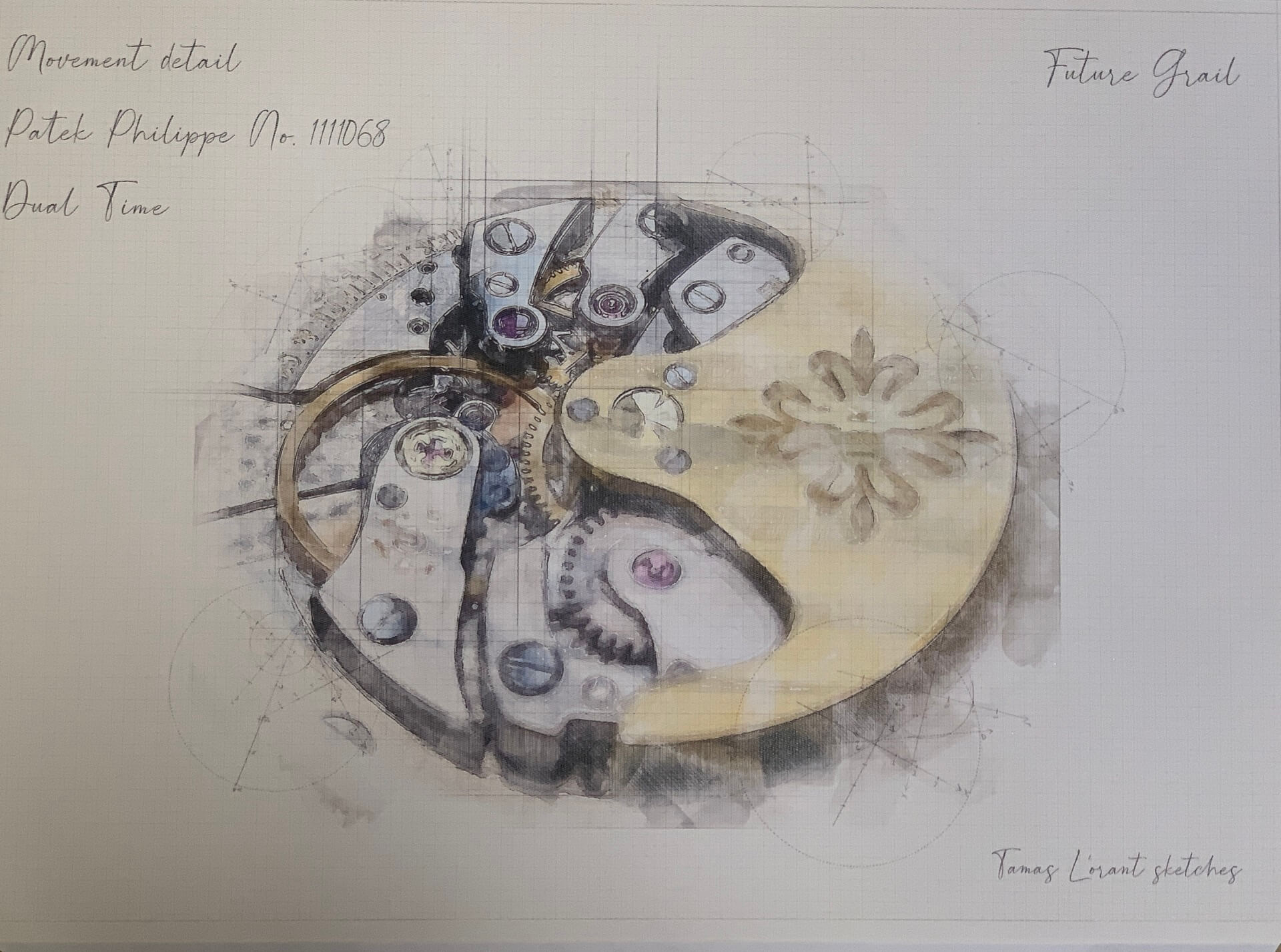

During our conversation, Ali suddenly stood up and returned with an exceptionally rare, one-of-a-kind, hand-engraved gold dial Patek Philippe Ref:3452 movement in hand.

“Unfortunately, the original case is missing,” he said, pushing it across the table toward me. “But the PP company only made 6 of these movements back then.”

He then asked if I would take on the task of creating a unique gold case for it according to his concept.

I felt that I was facing one of the greatest challenges of my career, but I also knew that it was these types of tasks that give meaning to my work. I happily said yes!

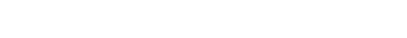

As it turned out, for the design, I only received photos, and they did not depict the case from every angle – as only a few were made, and they were not properly documented. So, I had to create a new case for the movement, not based on exact measurements but by using the forms seen in the photos and relying on my creativity. The technical complexity of the task was further complicated by the stepped design of the lugs soldered to the case and the practical challenges of finishing. Taking all these into consideration, I asked for a deadline of 8 to 12 months.

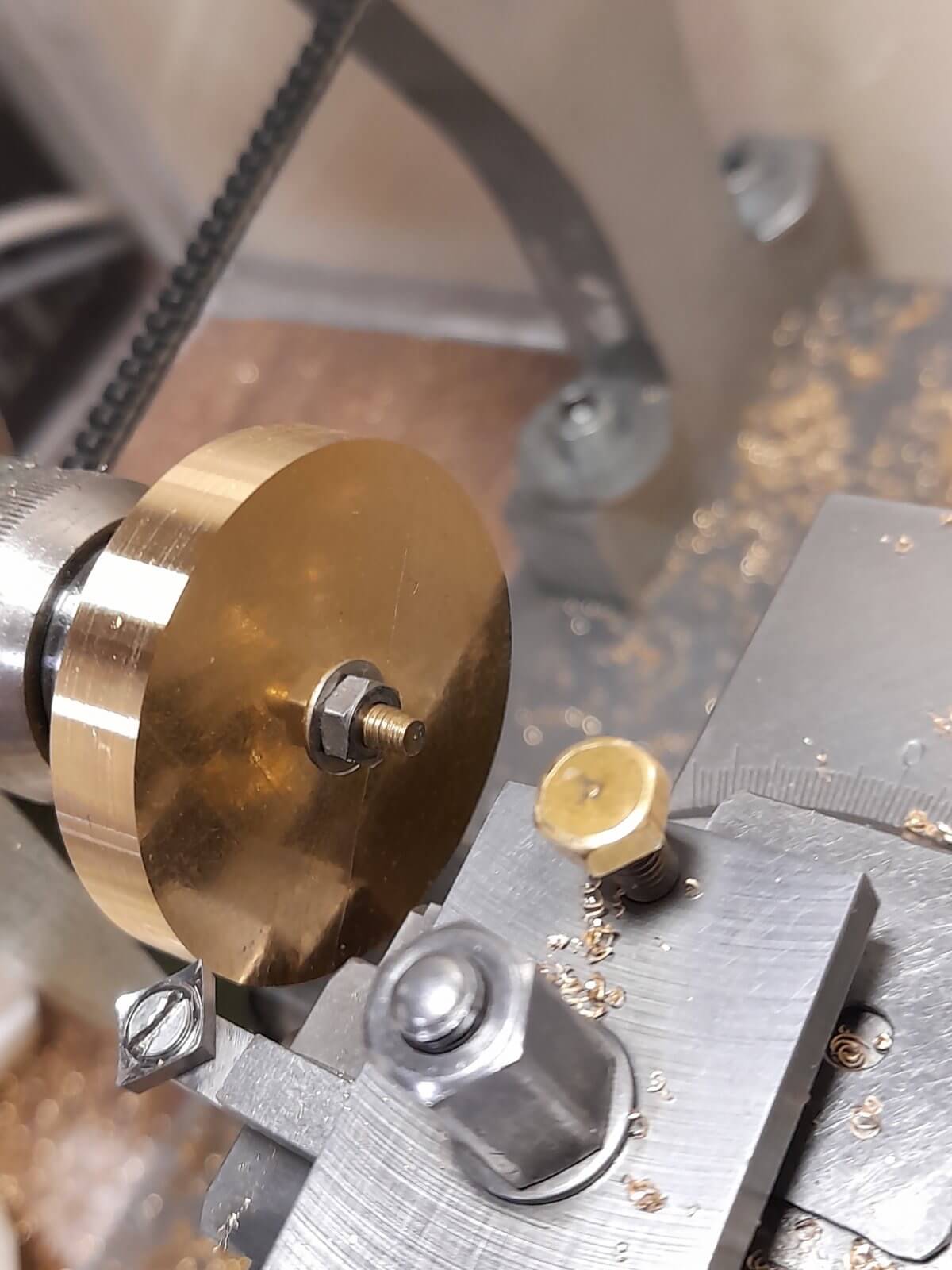

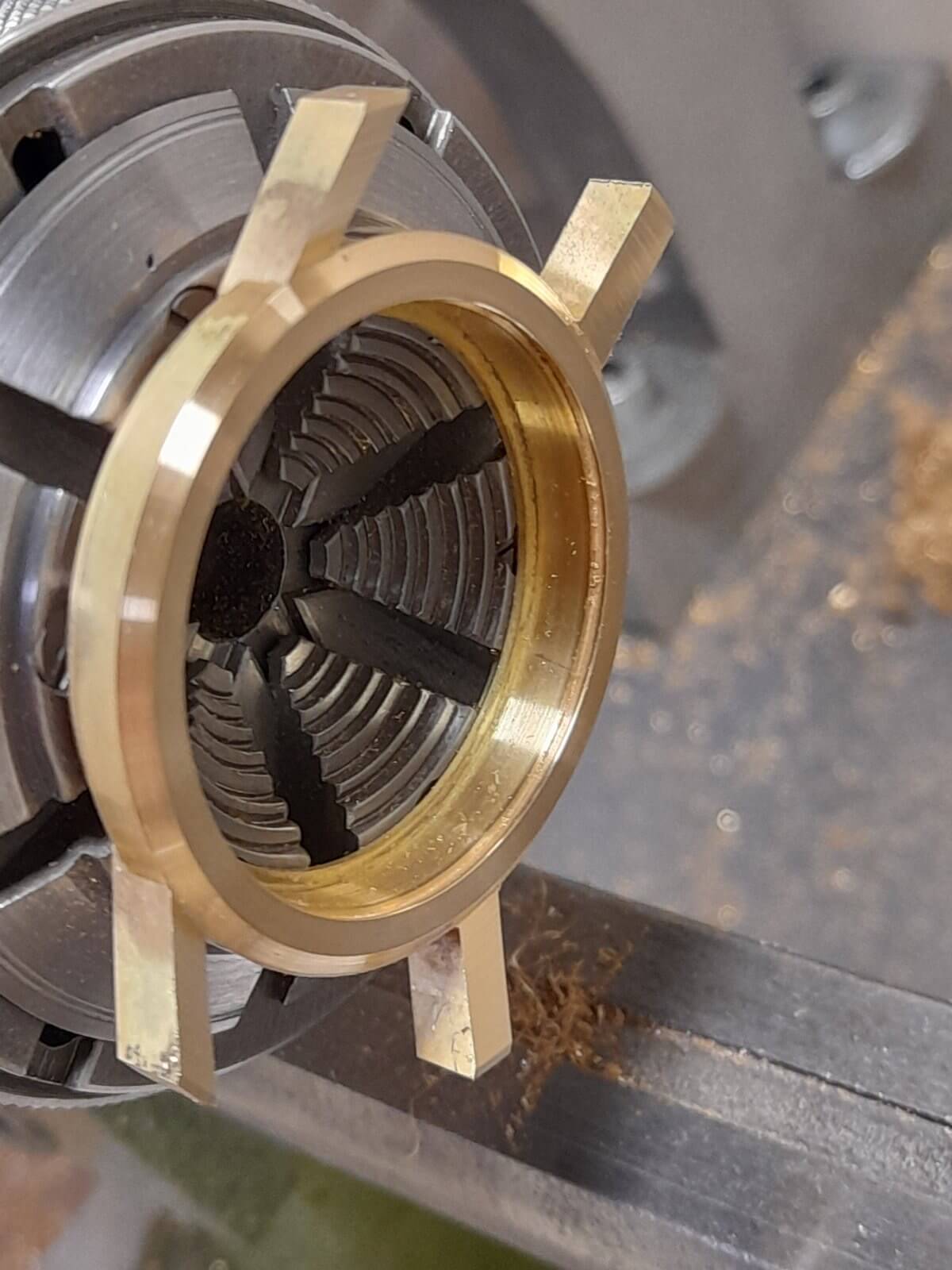

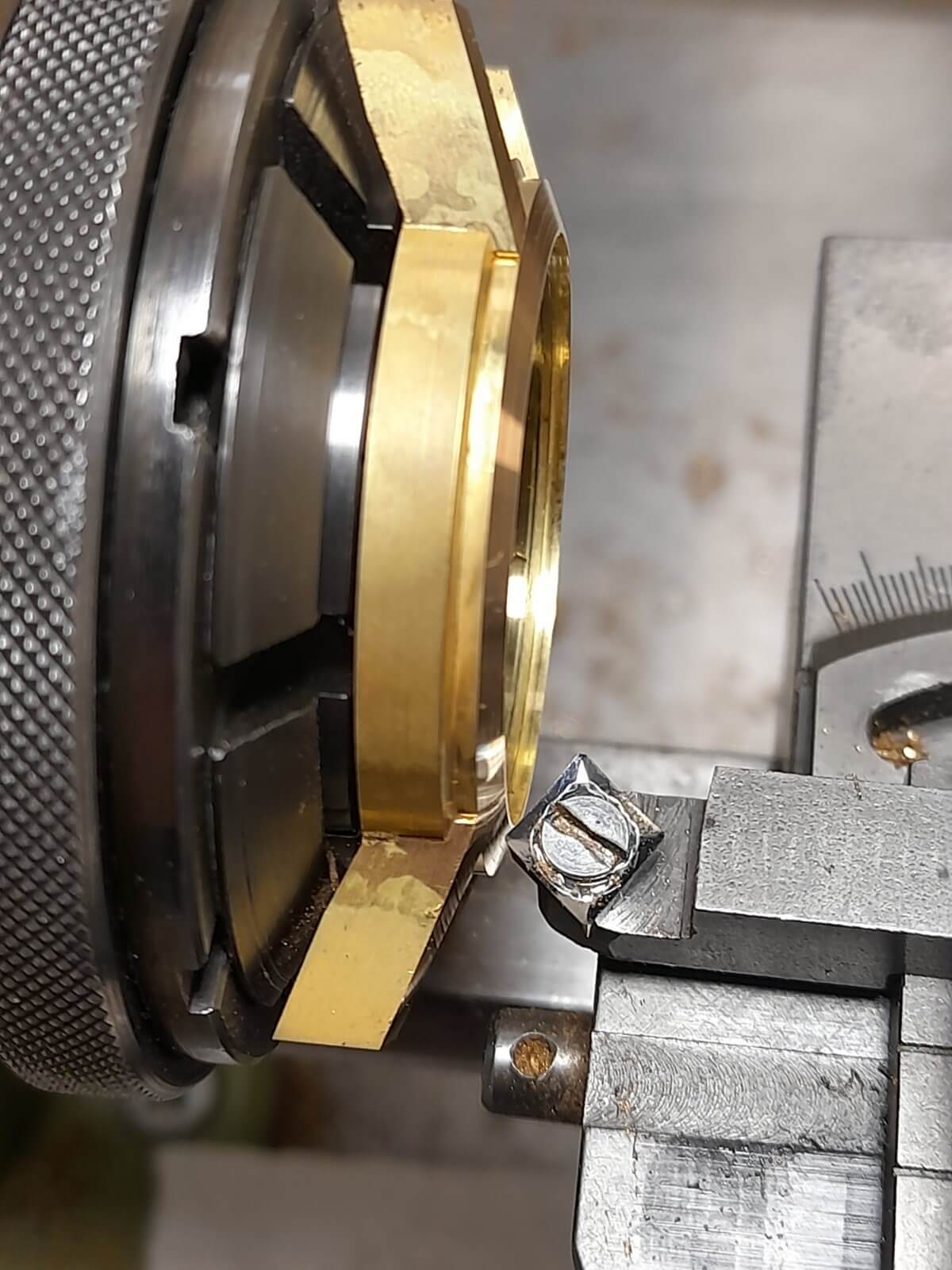

As with every unique watch I make, I began by creating the visual designs, and after presenting and getting approval for them, the creative process could begin. First, we made models out of copper to try out the sizing and proportions. Once the proportional case form was settled, we made custom soldering templates for attaching the four lugs. The basic shape of the case was created using traditional techniques, with a lathe machine, and the material requirement for the two-part, 18-carat gold case was over 600 grams.

After the lugs were created by wire spark cutting, they were attached using soldering and the template, and only after that could we start forming the final shape of the case. The real challenge came next, as the steps on the lugs could only be created by hand carving. Solving the precise fitting of the cone-shaped bezel and flat surfaces was a real challenge. We had to carefully plan the sequence of steps to ensure that all the surfaces would be polishable and sandable. For this, we had to manufacture special tools and apparatus. Then, there was the task of creating and inserting the push-button used to set the hands. The case back was fitted with a snap-on rim with a precision of 0.01-0.02 mm, and a sapphire crystal was inserted to showcase the beautiful automatic movement.

Throughout the process, I had to keep in mind that I was creating a case for an incredibly high-quality, rare movement, and it needed to represent the same level of expertise and quality, so I did everything in my power to meet this challenge. Due to the complexity of the task, I also sought the professional assistance of watchmakers and engravers – I am so grateful to them and thank them for their labor.

After a year of planning, preparation, and work, this exceptional dual-time movement came back to life, and now it shines and works in its original brilliance!

The watch was handed over on December 3, 2024, at the Mandala Club in Singapore. (Link: A Private Members Club | Mandala Club Singapore Mandala Club)

We introduced the guests of the club to the details of the creative process, allowing them to ask questions about every aspect of the work, and at the end of the evening, my client, Mr. Ali Nael, personally received the watch. To quote him, “We’ve created a historical piece,” and, “although he thought the watch would be beautiful, the final result exceeded his expectations in every detail.” Only then did he reveal that this special watch was originally made for the late Libyan President Moammar Gadhafi. So, the piece was included in the museum collection, where it can be viewed by appointment along with other horological rarities.

I am deeply grateful to the entire Futuregrail team, and personally, I thank Mr. Ali Nael for entrusting me with such a special, challenging professional task!